MAXJOLNT ELASTLC

MAXJOlNT ELASTlC is a two-component product. Component A is a liquid based on special synthetic resins. Component B, supplied in powder form, as a mortar based mixture of cements, additives and special aggregates.

When both components are mixed, an elastomeric product with high bond strength is achieved, suitable for sealing joints and cracks in concrete, pre-cast elements, mortars , bricks or other porous surfaces.

Application Fields:

• Sealing expansion joints with an in-service joint movement up to 15%

• Joints in permanent immersion in pipelines, water reservoirs, water treatment plants, etc

• Joints of concrete prefabricated elements and ceramic in façades and building construction

• Sealing of active cracks in concrete and masonry

• Pointing mortar on all porous substrates subject to movement

Advantages:

• Excellent adhesion on damp surfaces. Will bond totally to green/wet concrete. No bonding agent needed.

• Allows movement capability of joint up to 15%

• Very high weather resistant and durability. No maintenance required

• Non-slump on vertical joints

• Suitable for joints in permanent contact with water

Positive and negative:

• Easy to apply and finish

• Non-toxic, non-flammable, environmentally friendly

• Can be painted once cured with the desired colour

Or coated over using Maxseal Flex

Joint size:

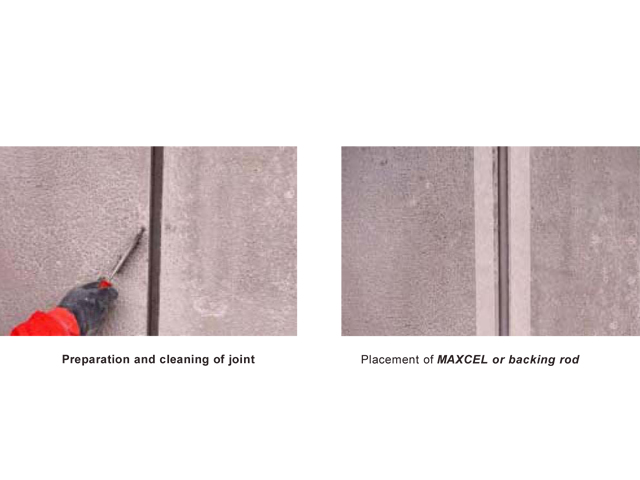

Joint must not be wider than 30 mm . Sealing depth should be at least half of joint width. Use polyethylene foam joint backing rod or MAXCEL with a diameter 25% greater than the joint width, in order to avoid stress of the bottom of MAXJOlNT ELASTlC.

Substrate preparation:

Substrate preparation:

The surface to be sealed must be solid and clean, free of all traces of paint, efflorescence, loose particles, grease, form-stripping oils, dust, gypsum plaster, etc. Before applying MAXJOlNT ELASTlC, dampen joint edge removing free-standing water. Mix preparation

MAXJOlNT ELASTlC is supplied as two pre-weighed components . Pour the res in, component A, into a clean container and add the powder gradually, Component B, while mixing with a low speed mixing drill (400 - 600 rpm), until a homogeneous mixture free of lumps is achieved. Avoid excessive mixing time and do not modify the proportions supplied between both components. Leave the mix to rest 2 minutes. Depending on relative humidity and temperature, pot life can vary between 30 - 60 minutes approximately After this time, remix to keep its workability but do not add water.

Application:

To improve the surface adhesion, a primer of Component A- applied by brush to the joint edge is recommended. While the primer coat is still wet to touch, apply MAXJOlNT ELASTlC into the joint by trowel , caulking gun or putt y k nife. Apply against the bottom edge of joint in order to avoid any remaining internal air bubble. For smoothing the surface, soaped water can be used immediately after application.

Application Conditions:

Do not apply MAXJOlNT ELASTlC below 5 ºC or if lower temperatures are forecast within 24 hours after application. Do not apply onto frozen or frosted surfaces.

Prevent fast drying during the first hours of curing. Protect against strong wind or direct sunlight at high Preparation and cleaning of joint temperatures . Do not apply if rain is expected within 6-8 hours after application.

Curing:

Curing time varies depending on temperature and relative humidity, as wel l on the joint size. At 20 ºC and 50 % R. H., a 10 mm width application of MAXJOlNT ELASTlC can be coated by MAXSEAL FLEX (Technical Bulletin nº29) after a curing time of 7

days.

When subject to water immersion, allow a curing time for 3 weeks, in such weather conditions. If application is done below 10 ºC, high relative humidity or unventilated areas, longer curing time is required.

Cleaning:

Tools must be cleaned with water immediately after application. Once the material hardens, it can only be removed by mechanical methods.

Packaging:

MAXJOlNT ELASTlC is supplied in 10kg pre-weighed sets ( 5kg liquid component A and 5kg powder component B ). It is available in standard grey colour. Other colours are available on request.

Storage:

Twelve months in its original unopened sets, in a dry covered place, protected from frost, above 5 ºC.

Consumption:

MAXJOlNT ELASTlC fills approximately 0,790 litres with 1 kg product. The following data is an approximate guideline depending on the joint size.

Important warnings:

Do not add cement , water or aggregates to MAXJOlNT ELASTlC to achieve higher coverage. Do not apply MAXJOlNT ELASTlC below 5 ºC or if lower temperatures are forecast within 24 hours after application.

Do not apply onto frozen and frosted surfaces. For further information, please consult our Technical Department.

SAFETY AND HEALTH

Component A: NON toxic, NON flammable. It is not classified as dangerous material f or transportation. Component B: as all cement based product, is an abrasive and protective rubber gloves and safety goggles must be used when preparing the mix and during application.

If any of the components or mixture gets in contact with eyes or skin, rinse with clean water, but do not rub. If irritation continues, consult a doctor.

A Material Safety Data Sheet is available for MAXJOlNT ELASTlC on request or is down loadable from website.

Disposal of the product and its empty containers must be according to official regulations. The proper disposal of the product is the responsibility of the user.

Website

Send Enquiry To Scientific Waterproofing Products Pty Ltd